Application prospect of UHMWPE fiber

Because UHMWPE fiber has many excellent characteristics, it shows great advantages in the high-performance fiber market, including mooring lines in offshore oil fields and High-Performance Lightweight composites, and plays a decisive role in modern war, aviation, aerospace, maritime defense equipment and other fields.

Defense

Because of its good impact resistance and large specific energy absorption, the fiber can be made into protective clothing, helmets and bulletproof materials in military, such as the armor protection plate of helicopters, tanks and ships, the protective shell cover of radar, missile cover, bulletproof clothing, stab proof clothing and shield, among which the application of bulletproof clothing is the most noticeable. It has the advantages of softness and better bulletproof effect than aramid, and has become the main fiber occupying the American bulletproof vest market. In addition, the U/P of UHMWPE fiber composite is 10 times of that of steel, and more than 2 times of that of glass fiber and aramid fiber. The bulletproof and riot proof helmets made of this fiber reinforced resin composite material abroad have become substitutes for steel helmets and aramid reinforced composite helmets.

Aviation

In aerospace engineering, due to its light weight, high strength and good impact resistance, the fiber composite is suitable for wing tip structures of various aircraft, spacecraft structures and buoy aircraft. The fiber can also be used as a deceleration parachute for the landing of the space shuttle and a rope for suspending heavy objects on the aircraft, replacing the traditional steel rope and synthetic fiber rope, and its development speed is extremely rapid.

Civil aspect

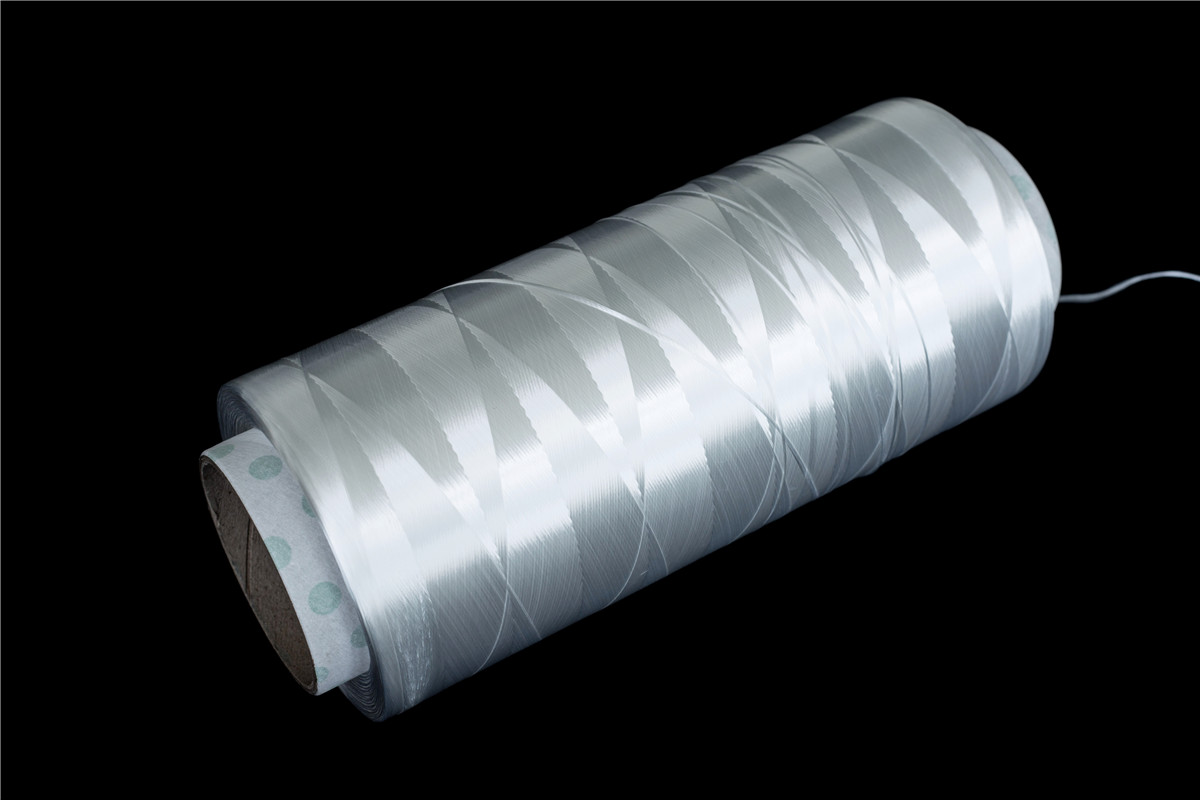

(1) Application of ropes and cables: ropes, cables, sails and fishing gear made of the fiber are suitable for marine engineering and are the original uses of the fiber. It is widely used for negative rope, heavy load rope, salvage rope, drag rope, sailing rope and fishing line. The breaking length of the rope made of this fiber under self weight is 8 times that of steel rope and 2 times that of aramid fiber. The rope is used for fixing anchor ropes of super oil tankers, offshore operation platforms, lighthouses, etc., and solves the problems of corrosion of steel cables and corrosion, hydrolysis, UV degradation of nylon and polyester cables in the past, which cause cable strength reduction and fracture and need to be replaced frequently. (2) Sports equipment and supplies: safety helmets, skis, sailboards, fishing rods, rackets, bicycles, gliders, ultra light aircraft parts, etc. have been made on sports goods, and their performance is better than that of traditional materials.

(3) As biomaterials: the fiber-reinforced composite material is used in tooth support materials, medical grafts, plastic sutures and other aspects. It has good biocompatibility and durability, and has high stability, and will not cause allergy. It has been used in clinical applications. It is also used in medical gloves and other medical measures.

(4) In industry, the fiber and its composites can be used as pressure vessels, conveyor belts, filter materials, automobile buffer plates, etc; In construction, it can be used as wall and partition structure. Using it as reinforced cement composite material can improve the toughness and impact resistance of cement.

Uses: bulletproof vest and helmet, light armor, sail, cable, optical cable reinforcement parachute and filter material, etc.

苏公网安备 32108102010466号

苏公网安备 32108102010466号